About WhiteXtar®

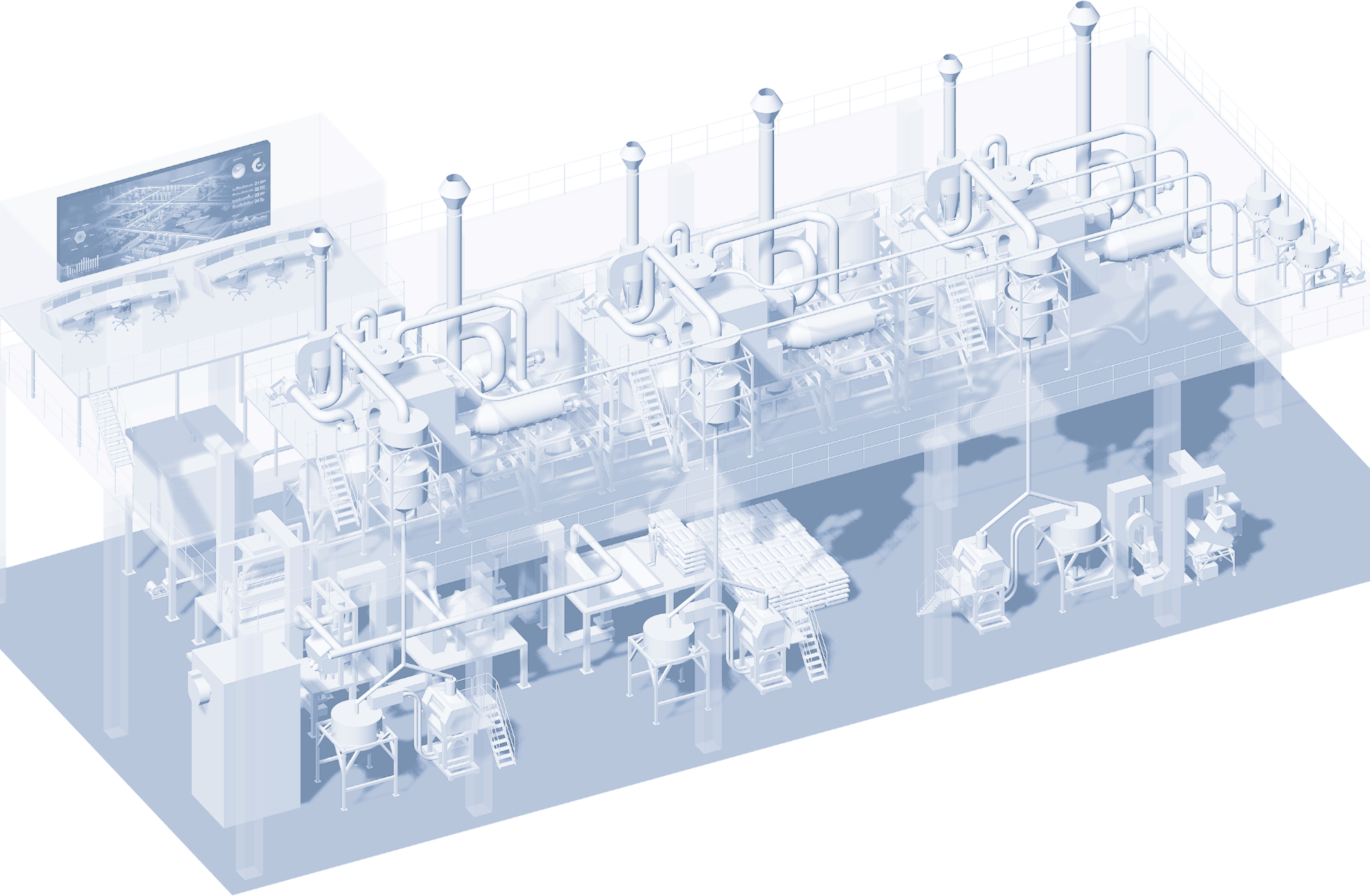

WhiteXtar® It is an innovative food factory created by a group of highly creative young professionals. Not only does it possess the capabilities of a conventional production-oriented factory, but it is also a company that pursues creativity, respects research and development, and leads industry transformation. We rely on constantly breaking through underlying technologies and an increasingly powerful R&D team, integrating learning and research, and integrating disciplines to explore and explore new fields with enthusiasm, providing long-term value to our customers.

The largest domesticfreeze-drying factory

No.1

National Coffee RoastingAnnual Capacity

TOP.5

Freeze-Dried Coffee PowderAnnual Capacity Reaches

1Thousand

tons

Coffee Factory Deploys

Globally

x4

Annual production capacity of coffee beans:

20,000+ tons

20000t

A super factory with a total plant area of

more than 80,000 square meters

80000m²

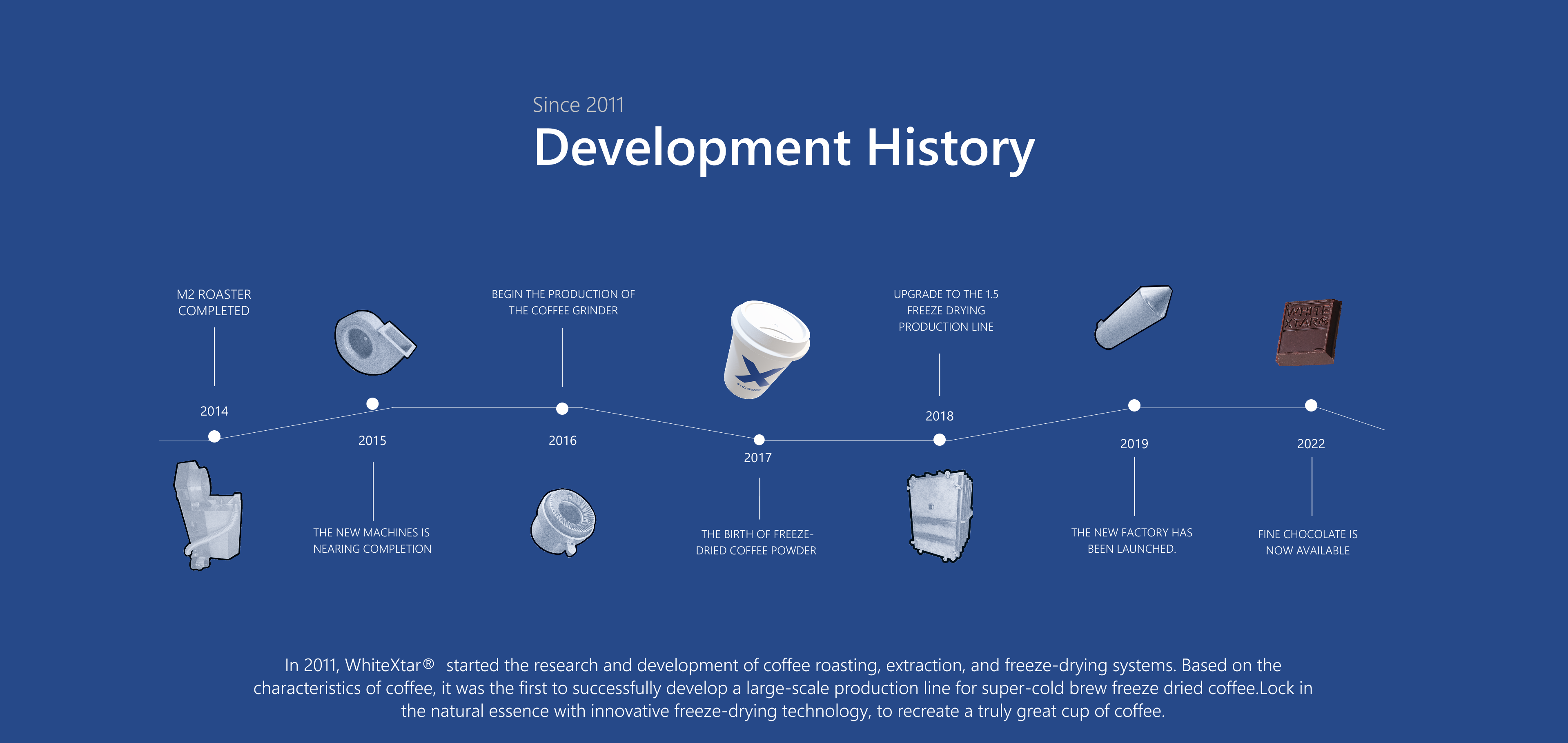

Development History

-

Roasting SystemPrecise temperature control to replicate various roasting profile and flavors

Roasting SystemPrecise temperature control to replicate various roasting profile and flavors -

Extraction SystemExclusive patent control system ensures extraction without limits.

Extraction SystemExclusive patent control system ensures extraction without limits. -

Freeze-Drying SystemWHITEXTAR® R&D manufactured an exclusive coffee freeze-drying chamber tothecharacteristics of coffee extract.

Freeze-Drying SystemWHITEXTAR® R&D manufactured an exclusive coffee freeze-drying chamber tothecharacteristics of coffee extract. -

Canning SystemEnsure that every single freeze-dried powder presents a more dazzling crystalline form.

Canning SystemEnsure that every single freeze-dried powder presents a more dazzling crystalline form.

Roasting System

3 self-developed baking machines by WhiteXtar®

-

The average roasting time for a

batch of coffee beans is:115min -

Assuming an 8-hour working

day, the theoretical roasting

volume is:30t -

Coffee bean annual production

capacity exceeds120000t

400kg

Roaster

400kg

Roaster

400kg

Roaster

Storage System

Batching System

Selection

System

System

Color Selection

WhiteXtar® has continuously optimized and updated through market testing, and the independently developed filling system has produced the 7th generation of Diamond Crystal Series freeze-dried powder, with each piece meticulously crafted for exceptional quality.

-

Real-time production process

Real-time production process

information traceability -

The image upload to the cloud

The image upload to the cloud

storage can be saved for 2 years -

Scan the QR code to view product

Scan the QR code to view product

information

Global capacity layout

four-plant synergy strategy

-

No.3 Super BaseFully Automatic Hub

No.3 Super BaseFully Automatic Hub -

The Force Planning FactoryFreeze-Dried Coffee Benchmark Production Base

The Force Planning FactoryFreeze-Dried Coffee Benchmark Production Base -

Precision Manufacturing CenterCoffee Equipment R&D and Manufacturing Base

Precision Manufacturing CenterCoffee Equipment R&D and Manufacturing Base -

Phase FactorySouth East Asia Hub

Phase FactorySouth East Asia Hub

& product customization

-

Global independent procurement

Global independent procurement -

Strict selection of

Strict selection of

green beans -

Customized

Customized

roasting profile -

Flexible

Flexible

customization